History and References

Specialty Refineries Systems Design, Manufacturing and Operating Services:

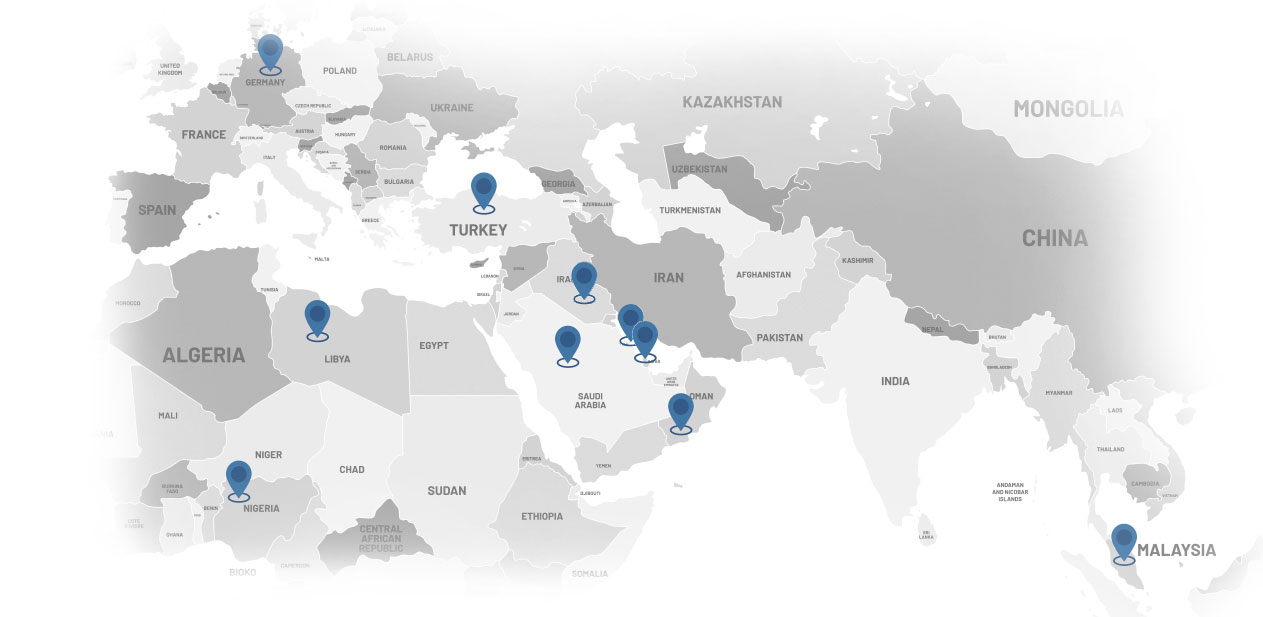

- NEW Patent in order to open up the market in the Arabian region and Nort h Africa. For technological process optimization in the production of high- octane gasoline.

- In 2006 CDT Group Development of simulation and optimization procedure for Hydrocracking Process.

- 2007/2008, Process simulation and optimization tests under different conditions and with tasks in the BRC-Refinery, Syria.

- In 2007, our engineering team conducted optimization at a CCR-platformer unit in the BRC refinery in Banyas, Syria. For technical reasons within the refinery, the final result was limited 2,9% increase in reformate. At the same time the octane number could also be increase by 0, 5 points. Without the technical inhibitions, the increase in reformate and octane number would have been significantly higher.

- In 2008, our team was able to optimize a CCR platformer unit with exceptional success with Alexandria National Refinery. As a result, the reformat was increased by 5.5%. At the same time the octane number was even increased by a whole point. At the time, this translated into annual extra profits for the refinery of about 240.000.000 US$. The economic value of enhancing the life-time of the catalyst has yet not even been included in this calculation. For our engineering success at the refinery, we received the corresponding references.

- 2009 Agreement with Otaiba Group in UAE - Abu Dhabi to Install Our System in ABU DHABI OIL REFINING COMPANY - (TAKREER).

- 2018 to Present Refineries: (4) Refineries in IRAQ. (1) Refinery in BULGARIA. Pilot Refinery, used for real dynamic test.