The Universal System Analytic Refining Application (UNISARA) Technology, which was developed in Germany, the Technology ensures Increase in efficiency of existing facilities by means of process optimization, meaning higher profits without extra investment for producing reformer units in oil refineries – with guaranteed increase in production from 1-8% by means of process optimization .

1. Summary;

Research, development, realization and application of the (UNISARA) Technology are summarized as following;

1.1 Optimization of the high-pressure CCR-Platformer (old UOP-system), optimization of the technological parameter leads to an increase of the final product by 2,9% and the octane number by 0,5 point.

1.2 Optimization of the low-pressure CCR-Platformer (new UOP-system incl. APC / OPT system )T, he optimization of the technological parameter lead to an increase of the final product by 5,5% and the octane number by 1,0 point.

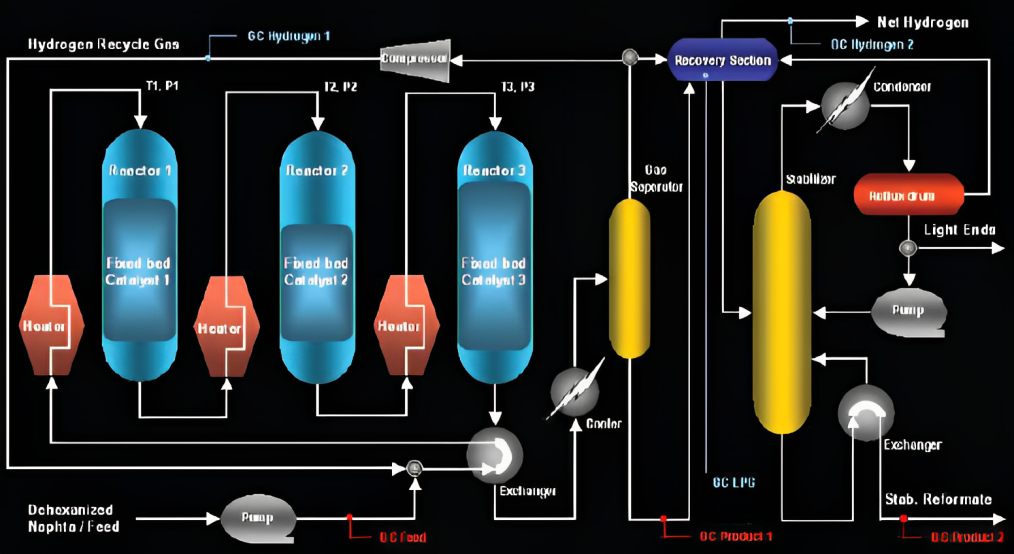

1.3. Scheme of fixed bed reforming:

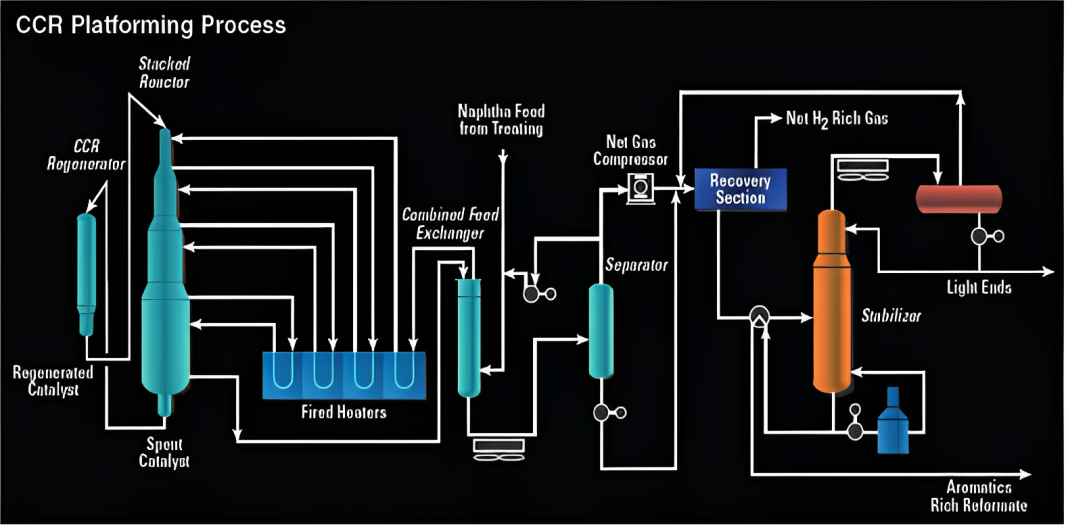

1.4. Scheme of fluid bed reforming

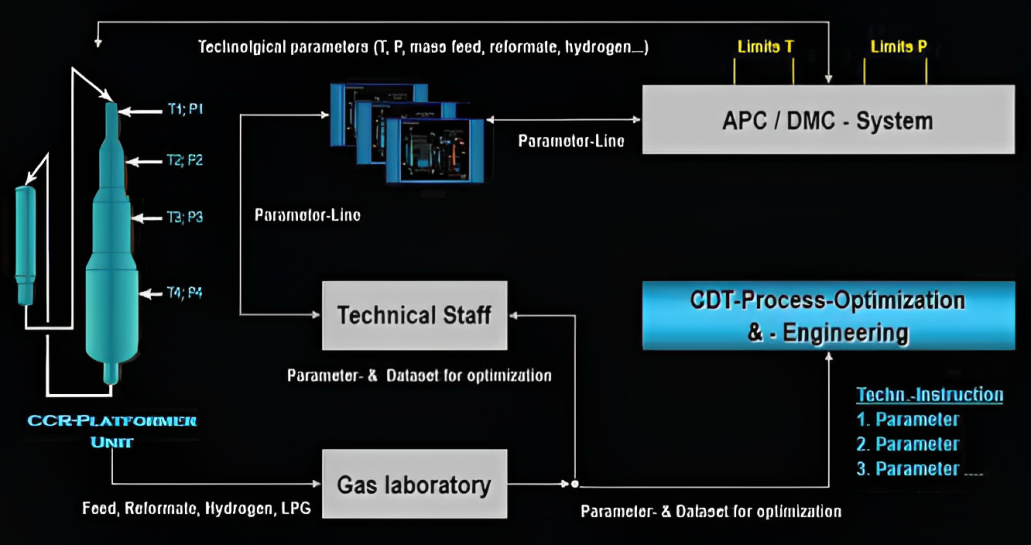

1.5. Adjustment of process optimization

2. UNISARA Technology Advantages: