Recycling & Refinery HFO, FO, USED OIL, Sludge, off specific & all resulting from VR

CDT Specialized Refinery Systems:

CDT has different projects/refineries in the Middles East. All projects use CDT technology of Upgrading and Cracking Units.

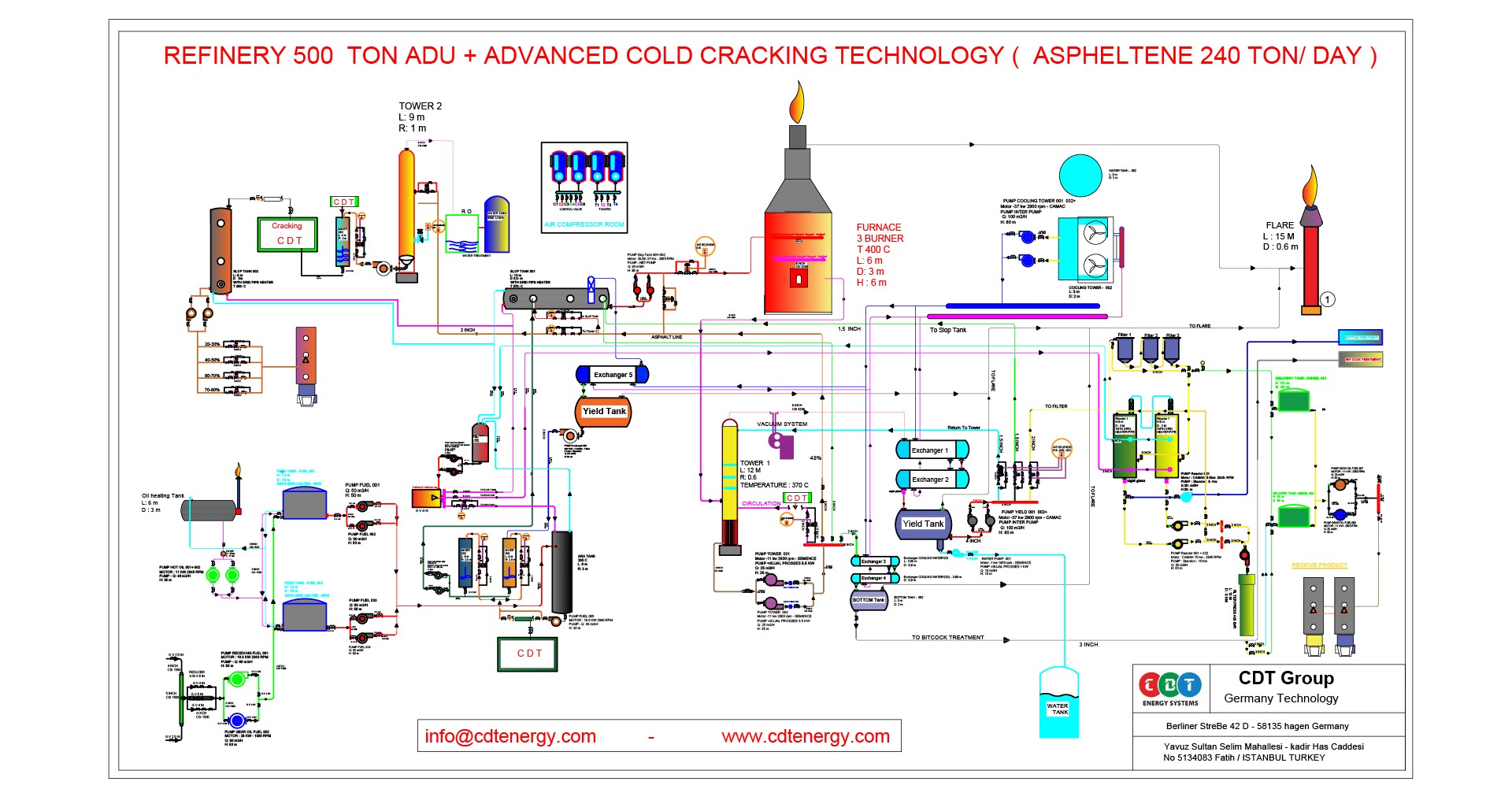

All the refinery systems and equipment developed by CDT with special KNOW-HOW and specialized refining system’s units of (Distillation Columns (VDU & ADU), Distillation Furnace, Heat Exchanger-Condensers, Reactors, Mixers / Blenders, Filters, The Thin Film Evaporators, Vanadium Inhibitor, and treatment / recycling with special designed Catalyst Cracking units with liquid catalyst or without, depends on the nature of the project and feed.

All units mentioned above have customized design and specifications, special design software’s are implemented, with other technical programs, corrosion-resistant, heat-tolerant and pressure resistant, Manufacturing of these units and equipment is done with international standards like ASTM, ASME & API standards. Achieves the goal of increasing the profit margin of the refineries at a lower cost. German / TÜV certified Upgrading & Cracking.

Joint Venture with Certified Manufacturers internationally and in Germany. Wide range of very effective Catalysts.

Can be deployed by any refinery using existing infrastructures with no costly modifications.

Generate high-value yield stock out from all types of low-value feedstock.

Safe system, does NOT require extreme pressures/temperatures.

Project pays itself within short period.

CDT has built two refineries in North of Iraq (up to 50,000 bbl/ day) for dynamic processing, to produce gasoline, naphtha, kerosene, diesel and base oil.

CDT has built refinery system to convert used oil to high quality lubricant oil with capacity 250 ton per day.

Two refineries to convert kerosene to white spirit with capacity 1,000 ton per day.