(ZDL) Zero Discharge Liquid & Environmental Solutions

CDT designs, integrates and globally markets turnkey systems for automated full solution waste oil recovery, Tank cleaning and sludge treatment system containers for Oil and Gas and petrochemical industries. CDT offers a combination of waste oil treatment and recycling (such as Sludge, Pit Oil, Spill Oil, Slop Oil and Drilling Mud) separation, treatment and recycling of the cleanedout waste oil. We specialize in environmentally friendly non-man entry oil tank cleaning and oil recovery system containers using safe and cost-effective methods.

CDT solutions help increase oil recover, reduce processing time and overall down time, near 100% recovery of hydrocarbons with minimal waste disposal CDT solutions are designed for optimum Health, Safety and Environmental (HSE) performance.

Tank cleaning, sludge and Waste Oil recovery services and systems are offered with CDT specialty technologies, Know-how and investment (according to the size and type of the project); assuring successful implementation and adherence to quality, local and international standards and customer satisfaction. (ZDL: Zero Discharge Liquid Systems that don’t leave any drop of hydrocarbon to loss or waste).

The fact that waste oil (Slop and Sludge) is a mixture of a wide variety of components, CDT offers specialty technologies and add-ons to make it possible to provide the complete system for each project nature and size. CDT Waste Oil Separation, Tank cleaning, Sludge and Slop Oil Treatment systems are designed to treat waste oils with a wide range of characteristics, from oils with a high solid content to oils with excess water in free and emulsion form. The core technology of the CDT system is based on application of several integrated technologies to solve complex hydrocarbon waste problems. In addition, our environmentally friendly biochemicals as 100% natural mix does rupture the bonds between hydrocarbons and other materials such as silt, sand or to the surface which eases its recovery. Additionally, it will render the other above mentioned sludge components soluble, facilitating removal, pumping, separation or any other desired function. Resulting in creation of marketable and value products. The rejects in form of water and solids are further treated for use in irrigation and bio-remediation of solid waste. Each system is specially designed according to the project requirement and nature, and is manufactured in custom-sized containers and suitable for use on remote sites and harsh environments.

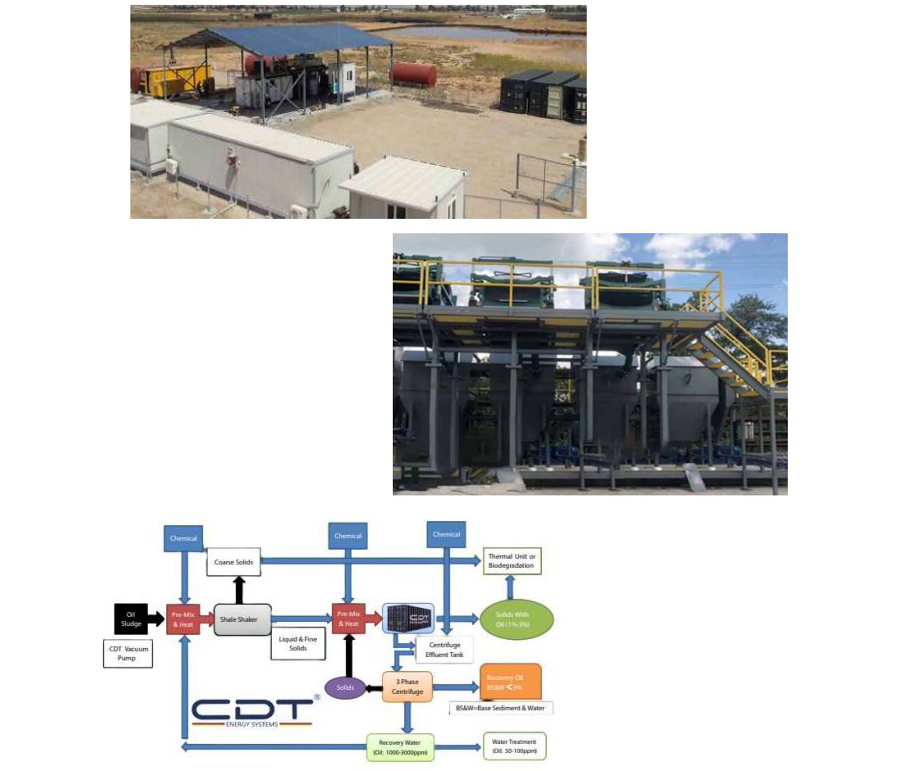

CDT Separation and Upgrading unit with Centrifuges purged with nitrogen, available for operation on site

Container system for the processing of Waste Oil, Refining Residue Sludge and Drilling Mud