1. Brackish Water comes into the CDT unit.

2. CDT unit processes water in cavitation reactor which is used as heater. Water changes the state to a steam.

3. Steam comes to condensation unit and changes state to a distilled water.

4. Unit requires power which can be produced from renewable sources like wind and solar energy.

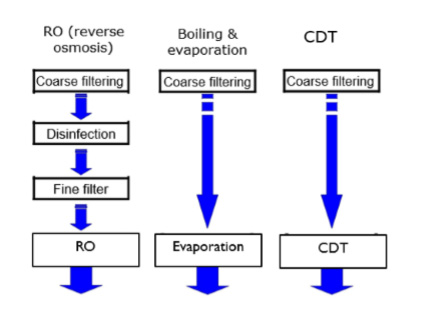

| Ro (reserve osmosis) |

Boiling distiller* | CDT | |

|---|---|---|---|

| Pre-filtering | Required | Required | Required |

| Disinfextion | Required | No | No |

| Fine-filtering | Required | No | No |

| Desalination quality |

99.% average | 100% H20 Salt:<10g perliter> |

100% H20 Any(!) % of salts |

| Scurf & sediments | Yes | Yes | No(!) |

| Dependence on % of includes in water |

Yes, strongly depends |

Scurf dramatically grows if % of salt is high |

Almost no dependence |

| Ro (reserve osmosis) |

Boiling distiller* | CDT | |

|---|---|---|---|

| Pre-filtering | Yes | <100um | <100um (normal pump requirements) |

| Fine-filtering | <<1um | No | No |

| Disinfextion | 99% average | 100% H2O | 100% H2O |

| Scurf | Yes | Yes | No |

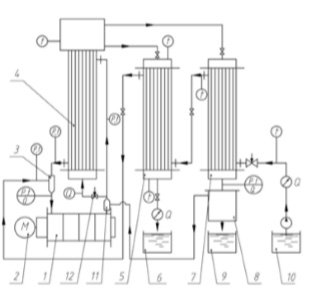

| Parameter | Value |

|---|---|

| Productivity | 40l per hour |

| Energy consumption | 40l per hour |

| Maximum avaible % of salt in water | 380V, 26 KW |

| % of salt in distilled water | No less than 100g per liter |

| W*H*L | No more than 0.1% |

| Weight | <700 kg |

| Mobile Versiyon | Yes |

Project Stages